THE SITUATION:

The injection moulding machines at ALPLA were experiencing higher than normal levels of contamination in their oil. The manufacturer of their injection moulding machines requires a cleanliness of ISO 16/14/11; anything less will void the warranty.

Routine maintenance of their injection moulding machine showed contamination was causing:

- Premature component wear

- Inconsistency of manufactured products

- Quality issues

- Increased downtime

Analysis showed contamination levels exceeded allowable limits, jeopardising their warranty

Backed by over 50 years of expertise, Triple-R took on the task of providing a solution to ALPLA’s injection moulding machines contamination issues.

THE SOLUTION:

As the industry leader in oil cleaning solutions, Triple R installed an oil cleaning unit onto the machine’s reservoir. The unit has a pump and motor which allows it to circulate oil through the housing without the need to use system pressure.

Equipment:

- SS103-1R Oil Cleaner

- M-Series elements

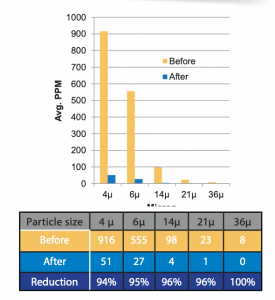

Achieved an average reduction in contamination levels of 95.25%

THE RESULTS:

After only 30 hours another sample was taken and the results were substantial;

- ISO Before: 17/16/14

- ISO After: 13/12/9

It was determined that there is no need for a costly oil change which saved the customer $8,000 and 24 hours of lost production time. In addition, analysis showed contamination levels were reduced to better than manufacturers requirements.

Triple R is a total oil cleaning solution that has been delivering innovative oil cleaning technology for over 50 years. We pioneered ‘total cleaning’ of industrial hydraulic and lube oil, guaranteeing oil purity and reducing environmental impact. Our scalable filtration systems can be customised to fit specific requirements worldwide, backed by 24/7 customer and distributor support.

Contact the Team at Triple R to assess your system requirements and solve unnecessary maintenance cost issues. Call our Keysborough Sales & Engineering Centre on (03) 7019 9351