TRCL Series

Model Types

- TRCL-100L

- TRCL-300L

Features

- This device separates foreign matters generated in coolant used in various machine tools, and further separates non‐magnetic materials including abrasive grain particles.

- The consumable parts like filters are not necessary due to separation by centrifugal force.

- The drain discharge is carried out for the separated objects as contaminated concentrate.

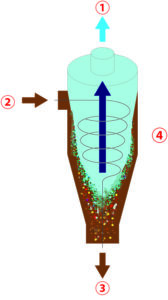

- Principle of Cyclone: 1) Discharge the increased clean liquid by cyclone effect. 2) Pump dirty liquid. 3) Discharge the sludge with condensed dirty liquid. 4) Flow of clean liquid.

Benefits

- Solid‐liquid separation by centrifugal force

- Operate regardless of oil or water-soluble.

- High wear resistance due to the body of stainless steel.

- Low running cost. No consumable parts like filters.

- Enable to check the captured sludge at pot visually.

Industries

- Agricultural Machinery & Road Transportation

- Automotive & Special Production Machinery

- Aviation, Aerospace & Military

- Construction & Tunnelling Machinery

- Electric Power, Diesel & Wind Turbine Generators

- Marine, Offshore & Container Handling

- Mining & Minerals Processing

- Paper, Pulp & Timber

- Petro Chemical

- Plastics, Presses & Extrusion Machinery

- Railway/Locomotive & Heavy Handling

- Steel & Primary Metals

| Model* | TRCL-100L | TRCL-300L |

|---|---|---|

| Order code | TR-21200 | TR-21000 |

| Pressure | Max 5 bar | |

| Typical flow rate | 100 l/min | 300 l/min |

| Element change out | 3.5 bar | |

| Element change out | Element change out from the top of the housing | |

| Fluid type | Suitable for mineral bsed hydraulic and lubricating oils. Units also available for water glycols | |

| Inlet/outlet ports | Rc1" x 1" | Rc1.1/2" x 1.1/2" |

| Drain port | R1.1/4" | R1.1/2" |

| Housing material | Stainless steel | |

| * More housings can be grouped together and further expanded. Assembled units can also be customised to suit installation and space requirements |

||